Your basket is currently empty!

Written by

What is an Expansion Vessel For Boiler Safety?

Most of us remain blissfully ignorant about the finer details of our heating system.

So, you’ve probably never given any thought to the expansion vessel however, this is a crucial part of a closed water heating system whether that’s a system, regular or combi boiler.

That’s because as the water heats and cools, the expansion vessel manages its expansion and contraction.

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

What is an expansion vessel?

An expansion vessel is a tank that keeps the water pressure inside a boiler regulated while water is heating and cooling.

Without an expansion tank working correctly, then you’re going to get boiler failure and that means no hot water or heat for your radiators.

In this guide, we’re going to provide you with everything that you need to know about expansion vessels and some of the most common problems they can experience. If need a new heating system then check out our new boilers online, ready to install nationwide.

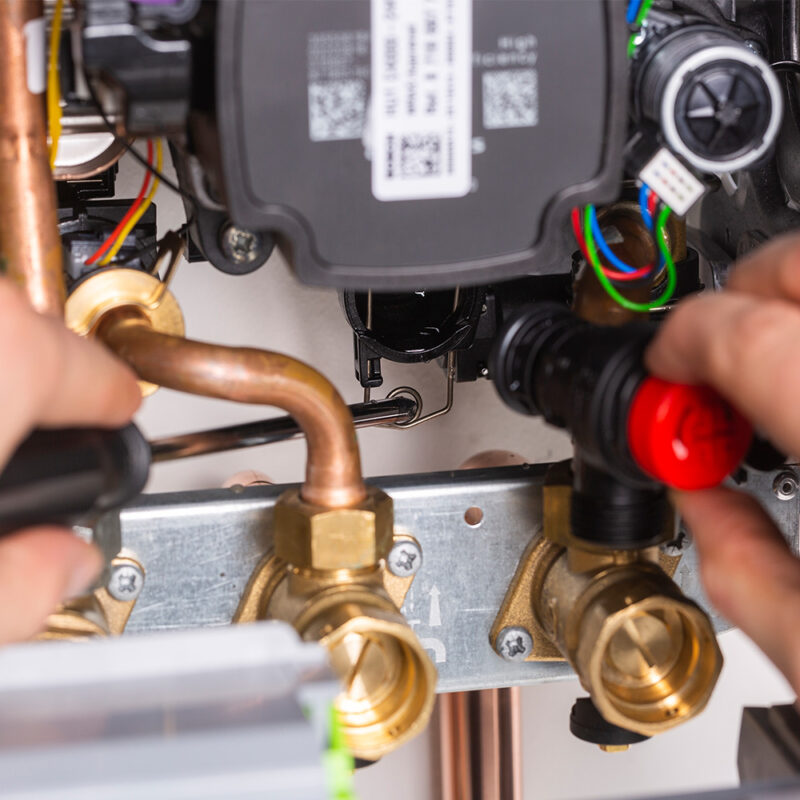

How does an expansion vessel work?

An expansion vessel contains both air and water. The water comes from the central heating system and fills one side of the vessel. Then nitrogen gas fills the other side.

Because water expands when it’s heated, that extra water needs somewhere to go. As most boilers have a sealed system, if the expansion vessel wasn’t there then the excess pressure would rise to the point of being dangerous. This would then cause the pressure relief valve to open up to balance out the issue.

By having an expansion vessel in closed water heating systems, there’s an overflow tank for that extra water and that then means that the pressure remains at a safe level.

Expansion vessels are often compared to a spring as the air or nitrogen on the inside is compressed. That means that the extra pressure is absorbed and the boiler pressure is kept stable.

The bladder or diaphragm expansion vessel

While there are different expansion tank designs, generally a modern heating system will have a type that’s called a bladder vessel. With these, there’s a flexible membrane or diaphragm that separates the water from the central heating water and the compressed air.

On the airside, the vessel also has a schraeder filling valve. This means that more air can be pumped in as and when necessary, to make sure that it’s able to provide resistance as the water expands.

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

Expansion vessel problems

Big swings in central heating pressure

When there are big swings in the central heating system pressure within a short period, then one of the most common causes is a problem with the expansion vessel. You’re going to know that this is a problem by checking the readings on the pressure gauge which is usually on the front of the boiler.

If the boiler pressure swing is more than 1/2 bar

This indicates that there there may be a problem with the expansion tank but more investigation is needed.

If the pressure swing is 1 bar or more

Now you can be pretty sure that you need to replace the schrader valve/air valve or a new expansion vessel needs to be fitted.

With this being such a crucial element of a heating system you’re not going to get the desired pressure without getting it repaired.

Undersized vessel

An undersized vessel can also cause big pressure swings. However, you would have noticed these swings ever since the installation.

The exception to this will be if you’ve recently added several more radiators to the heating system. This might then mean that the original expansion vessel is now too small to cope with the much larger circulation of hot water that’s now needed.

Diaphragm damaged

The internal bladder or diaphragm, is usually made from neoprene rubber because it doesn’t degrade in the same way that natural or synthetic rubber does. Damage can however still happen over time.

As the diaphragm becomes degraded, it becomes easier for the gas molecules to pass through it. That then means that even if it’s not perforated, the charge pressure can slowly reduce.

As a result the size of the air pocket reduces, and the vessel can no longer accommodate the water pressure due to the expansion. This then means that the boiler pressure begins to rise which causes water to be expelled through the pressure relief valve.

Can a damaged diaphragm be replaced?

Repairs to the diaphragm are not an option and so an engineer will need to replace the expansion vessel.

Faulty valve

With the tank re-pressurised, then it’s a good opportunity to also ensure that the Schrader valve isn’t leaking air. If the valve is faulty, then this could be the reason that the boiler pressure is causing problems.

The engineer will check this by placing some washing up liquid over the valve. If bubbles form then that’s going to mean that air is escaping and a replacement valve will be fitted.

It’s worth knowing that while there is a range of common boiler parts that are more likely to fail than others this valve doesn’t tend to be one of them.

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

Reduced level of air in the expansion vessel

When the level of nitrogen or air drops the boiler will have persistent low pressure problems which then create problems with the circulation of hot water around the heating system.

Part of the annual servicing of your boiler will be to re-pressurise the system when needed. This then prevents expensive call out fees and boiler repair costs. The re-pressurising is done by draining off the water and then using a pump (like a bicycle pump or similar) to reinflate the expansion vessel. Check out our guide on boiler service costs to get a clear idea of what you might need to pay.

Could the problem be caused by other issues?

It’s important not to leap to conclusions because there are other problems that could cause system pressure issues. These include leaks in the heating system and water pressure problems along with the issues caused by a filling loop that isn’t correctly connected. It’s worth knowing that a filling loop can be internal to the boiler while others are an external fitment.

Ensuring that you arrange an annual boiler service will spot and fix minor issues early on before they become big problems. It’s also worth bearing in mind that getting your boiler serviced will be less expensive than having to pay out for repair costs!

What size of expansion vessel do central heating system need?

A central heating system relies on the right level of boiler pressure to operate correctly. If your boiler is losing pressure or reaches high levels of pressure then there are going to be problems.

If you need a replacement vessel then the work has to be carried out by a gas safe registered engineer. This is because the boiler casing usually needs to come off to reach the expansion vessel

Can I replace the expansion vessel?

The UK has strict rules and legislation in place as to who can install, service or repair a gas appliance so it’s important to get a suitably qualified heating engineer.

You might also find that your boiler warranty becomes invalid if you attempt repairs yourself.

But, if you’re just curious, when the water is heated in the boiler, it can expand by around four to nine per cent. If the tank is too small, then the boiler expansion vessel isn’t going to be able to do its job.

External expansion vessels

There are a few models of boiler that have an external expansion vessel but we’d still recommend getting a heating engineer to check it out. With some boilers it is possible to replace a failed internal expansion vessel with an external one leaving the faulty one in place

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

What pressure should expansion vessels be set to?

The air within the expansion vessel needs to be at the correct pressure for it to be able to work correctly. If you’re not sure what this should be, then your boiler manual will provide the information needed to calculate the correct level for your model.

Testing a schrader valve

Pushing down on the schrader valve should result in the sound of escaping air. If that doesn’t happen then you’ll know that there are pressure problems. If water comes out then this suggests that there are problems with the central heating system, though this can sometimes happen because of condensation collecting on the pressure gauge.

An engineer will drain and then re-pressurise the expansion vessel to see if that then helps to achieve the correct boiler pressure.

However, if this doesn’t work, then there’s a good chance that the diaphragm is damaged and the vessel needs replacing rather than a fix.

Faulty expansion vessel: do I need a heating engineer?

You do, but also because as we’ve already mentioned it might not be the expansion vessel that’s causing the problem. That means that you’ll need a heating engineer to come and check out your boiler to then be able to assess what’s causing the problem.

The danger of carbon monoxide

Did you know that faulty boilers are some of the most common causes of carbon monoxide poisoning? Every year, around 60 people lose their lives due to this invisible and odourless gas? So if you need another reason to get that boiler servicing done, then this has to be it! And don’t forget to make sure that the your carbon monoxide detector is checked out at the same time

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

Do I get my boiler repaired?

The average cost of a boiler repair cost varies on where you are in the country and how old your boiler is. Even the best combi boiler can break down when we’re talking about older boilers then it might work out more cost-effective to get a replacement boiler rather than pay for repairs.

The cost of getting someone in to fix your boiler can quickly start to add up and once one element has become faulty there’s always the concern about what might be next. No one wants to be without heating and hot water in the colder months of the year, so a reliable boiler is essential.

This is when getting in a qualified engineer can help, they can give you an accurate diagnosis of the issues and an estimate for boiler repair costs.

Boiler age and efficiency levels

That’s because when heating systems are over eight years then they will have lost some of the efficiency they had when first installed. Boiler manufacturers have also introduced a number of new innovations that have seen a huge increase in the efficiency level you can expect from a system or combi boiler.

When a boiler has a low level of efficiency then that means higher fuel bills and increased carbon emissions. Read our guide to learn more about boiler efficiency.

Time for a new boiler system?

There will come the point when a fix just isn’t possible or cost-effective and that’s when looking at new boiler systems is the best option. Whether that’s for a combi gas boiler or a system boiler, then the next step is to get a no-obligation quote.

Getting a boiler quote

Knowing which unit is the right one for you can be difficult. But thankfully, this is where getting a quote for a new boiler comes in. With no obligation, you can now feel free to get a quote and see the recommended range of boilers for your hot water and heating needs.

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

Written by

Get the best quotes for boiler installation online in under 1 minute now

New Gas Boilers with FREE Hive Mini Smart Thermostat!

£0 Deposit & 0% Interest Finance available

What is in this article?

- What is an expansion vessel?

- How does an expansion vessel work?

- Expansion vessel problems

- Could the problem be caused by other issues?

- What size of expansion vessel do central heating system need?

- What pressure should expansion vessels be set to?

- Faulty expansion vessel: do I need a heating engineer?

- Do I get my boiler repaired?